Your Garage Transformed!

Your garage makeover begins with our epoxy & polyaspartic flooring process. Our installation experts specialize in turning old, dirty, or cracked concrete into a beautiful flooring surface that will make your garage the envy of the neighborhood. Every garage floor installation starts with our proprietary epoxy coating. Our coating has up to 3 times better adhesion quality than standard industrial-grade epoxy & polyaspartic coatings. Our product is a high build, hybrid garage floor coating system that is low in VOC content and consists of a colored epoxy base coat, vinyl color chips, and a long wearing polyaspartic or polyurea top coat. Our Roll On Rock® epoxy “fuses” deep into the concrete floor to provide the foundation needed to offer a “Lifetime Warranty”. Our epoxy won’t peel from the concrete floor… Period!

While the epoxy begins to “fuse” to the concrete, our experts apply the decorative media of your choice onto the epoxy, providing a seamless multi-color appearance to the entire garage floor. The final step is the application of our Ultra High Solids Polyaspartic clear top coat that will provide a smooth mirror-like gloss to your floor. Our Ultra High Solids Polyaspartic has fewer solvents, resulting in more build and less solvent odor than comparable garage floor coating systems.

FEATURES & BENEFITS

NO PEELING

Diamond grinding to ensure a superior bond

UV STABLE

The base coat will never fade and the top coat will never yellow

RESISTS CHEMICALS

Gas or oil will not harm the surface and can be easily cleaned

CRACK REPAIR

All cracks are filled before application

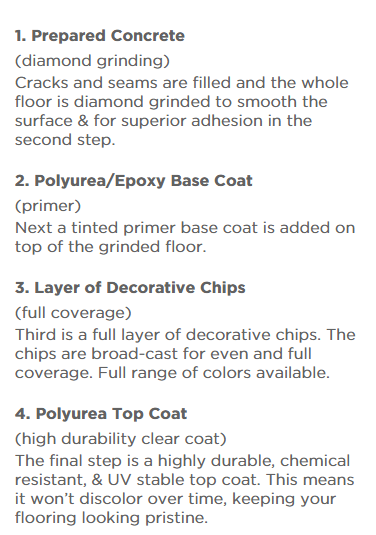

OUR PROCESS

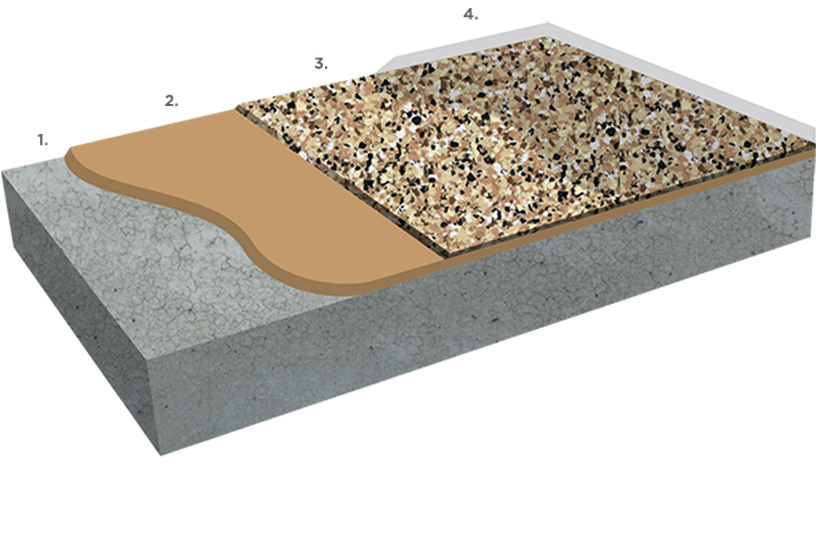

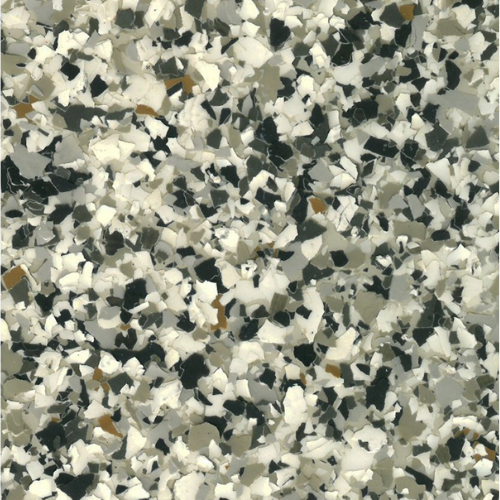

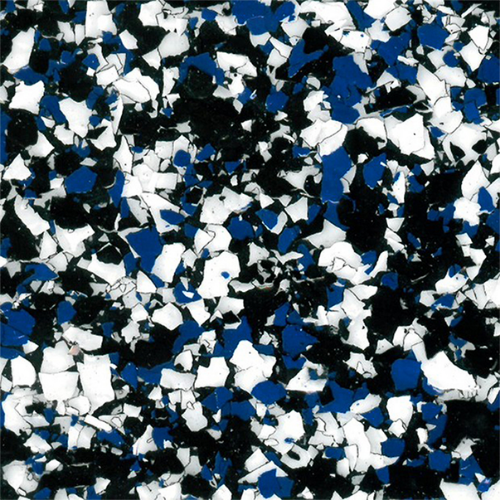

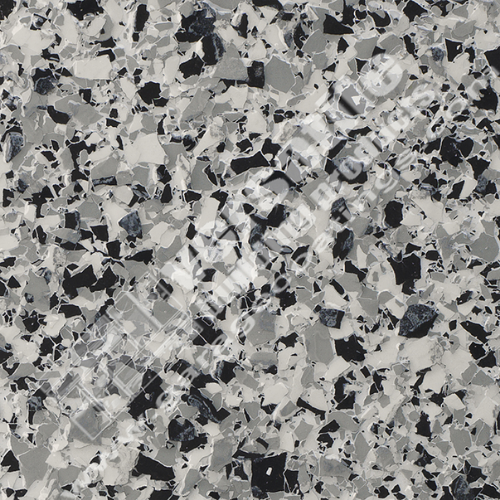

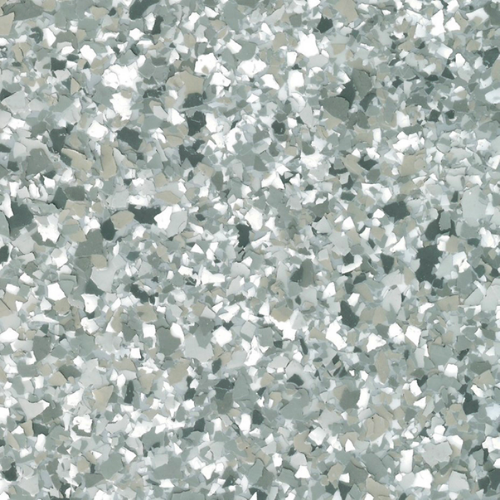

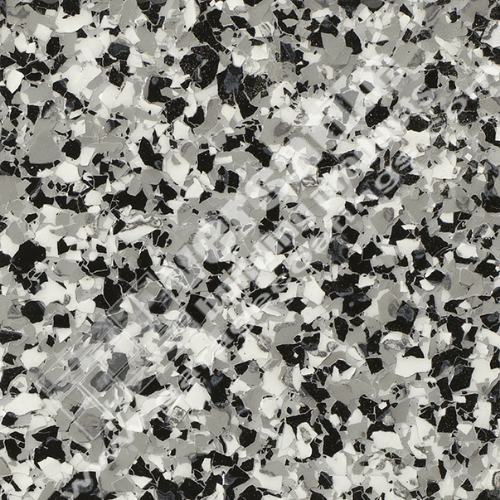

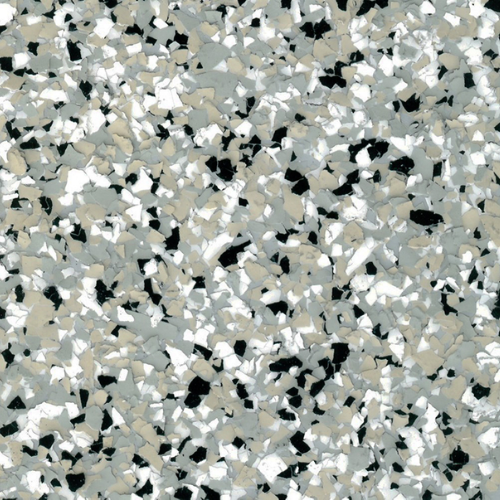

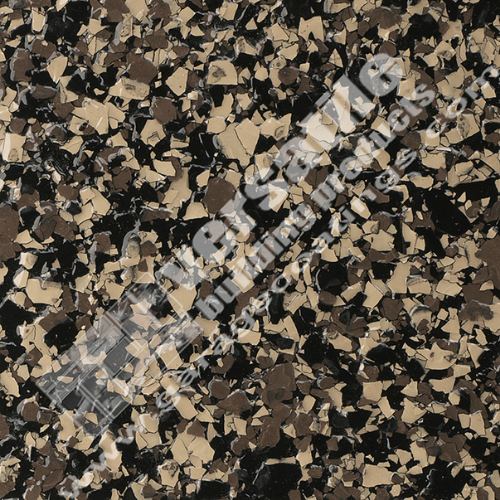

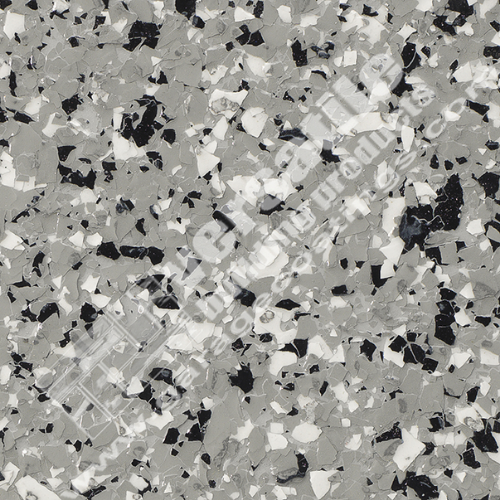

Blended Flake Selections

Mushroom

Nightfall

Creekbed

Saddle Tan

Touch of Blue

Graphite

Stoney Creek

Cappuccino

Tuxedo

Cabin Fever

Dakota Gray

Brown

Santana

Gray

Custom color combinations, solid color flakes, and metallic "bling" are available upon request.

FAQ

Most frequent questions and answers

There are several factors that will effect the overall cost of your garage floor transformation. With that said, we do have a base price of $5.30 per sq/ft.

Garage Floor Coating Cost Factors

- The size and layout of your space.

- What condition your concrete is in – is there cracks or pitting.

- Is there already a floor coating that needs to be removed.

Yes, everything has to be removed prior to the garage floor installation. Sometimes it may be necessary to rent a storage pod that sits in your driveway.

You may also feel comfortable storing your garage items outside with a large tarp to protect it. If you are unable to clear out the garage and need assistance, we can provide help with that at an additional fee of $65 pr/hr – pr/person

In most cases our coating system can be completed within 1-2 days.

You can start using your new floor the very next day,but we ask for an additional 1-2 days of cure time before introducing any vehicles to the surface.

Because we apply a nearly complete flake broadcast over the base coat, we find that this gives the final coated surface a texture that gives stability. The floor surface can get slippery because it is impervious to liquids. Just be aware of that possibility whenever the situation arises.

Oil and chemicals can be wiped up without staining the surface. You can clean by using a power washer, bristle brooms, and mops – using any cleaning solution.

WHAT IS ROLL ON ROCK®?

Roll On Rock® was first introduced in 1999 and has slowly evolved into the superior coating that is available today.

epoxy-stronger-than-concrete

It is a high build, hybrid garage floor coating system that is low in VOC content and consists of a colored epoxy base coat, vinyl color chips, and a long wearing polyaspartic or polyurea top coat. It sounds simple enough, but there really is more to it than that.

4195 EPOXY COAT

At the heart of this system is the 4195 Direct-to-Concrete Pigmented Epoxy that is used as the base color coat. This really is what makes Roll On Rock® somewhat unique when compared to other epoxy coating systems.

4195 is a proprietary blend of 95% solids epoxy that works like a primer. It wicks deeper into the concrete substrate than other high solids epoxy in order to form a very good mechanical bond.

The high solids content is low in VOC’s and provides for a good build coat and excellent medium to absorb the color flakes. It provides up to 8 mils dry film thickness dependent on the coverage rate.

Additionally, 4195 is formulated from Versatile’s moisture blocking 4150 Vapor Stop epoxy. The result is an epoxy base coat that can handle up to 8lbs of moisture vapor emissions (MVE). This is twice that of most high solids epoxy coatings. Thus, it can provide a large cost savings advantage if you have concrete with possible moisture issues since it would allow you to forgo the addition of more expensive moisture blocking epoxy primers.

COLOR FLAKE

What gives Roll On Rock® its granite like look, color, and high build is the vinyl color flake. This is achieved by applying the color flake into the 4195 epoxy to full refusal.

The most popular flake size to use is 1/4”, followed by the much larger 1” flake. With dozens of color combinations to choose from, this is where you can really shape the look of your coating to your preference.

5073 CLEAR TOP COAT

The clear top coat is what locks in and protects the vinyl color flakes. It also provides for the glossy look and long wearing surface.

5073 is both water clear and high gloss, plus it’s highly resistant to all the typical chemicals and fluids that you find in a garage environment. Once applied to the color flake you can expect an average dry film thickness of approximately 4.9 mils.

It is extremely resistant to staining from hot tires and it has a very impressive rating for abrasion resistance. This means that it is very durable and long wearing. In addition, the high abrasion resistance means it will resist scratching well and hold its glossy looks even longer. It’s what we like to call a high performance top coat.

Once the entire system has cured you can expect a total floor thickness of approximately 30-35 mils. With the combination of full vinyl color flakes and polyurea top coat, you will not have to worry about yellowing of the coating due to U.V. exposure.

We provide a “Lifetime Warranty” on product and application failure.

For more information head on over to our Warranty page

Partner With Us

We have a special proposal for Contractors, Builders, Remodelers, and Buisnesses who would like to provide our services with your branding.